ABOUT US

We are different, we look at the essence of product, we think for our consumers, we are creative and we strive to become the best company and to provide you the best product to satisfy you!

COB: This process is the bare chip using glue directly on the PCB board on the designated location. The chip electrode and the corresponding PCB board are connected through the aluminum wire of the welding machine. Then the chip and the aluminum wire are sealed and cured with black glue to realize the connection between the chip and the PCB electrode.

The advantage of this IC is a good sealing, solder joints and lines will not be damaged by the outside world, but at the same time if there is damage is not repairable, can only scrap treatment.

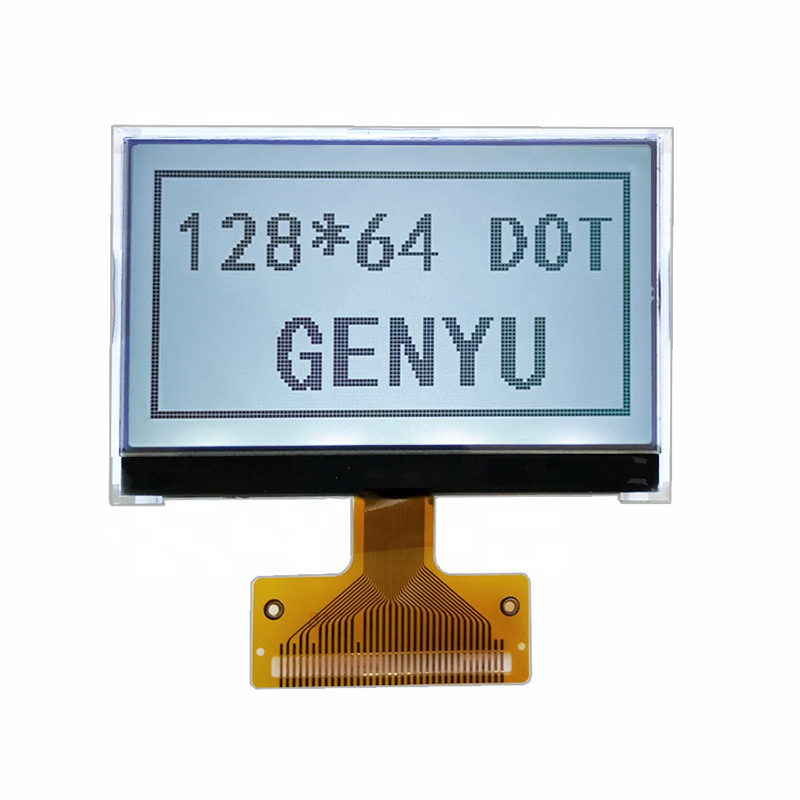

COG: This process is really focused on the small size of the LCD external leads. LCD dedicated LSI-IC dedicated chip in between, with pressure welding wire will be required to weld each end together, and then in the above drop casting a drop sealant can be. The input side of the IC operates in the same way. At this point the LCD chip to form a complete LCD module, just hot-press it and PCB board can be connected.

COF: The process involves pressing and welding an integrated circuit chip onto a flexible film conveyor belt, which is then connected to the external lead of the liquid crystal display using a non conductive adhesive, this is mainly used in small display systems.

COF: The process involves pressing and welding an integrated circuit chip onto a flexible film conveyor belt, which is then connected to the external lead of the liquid crystal display using a non conductive adhesive, this is mainly used in small display systems.

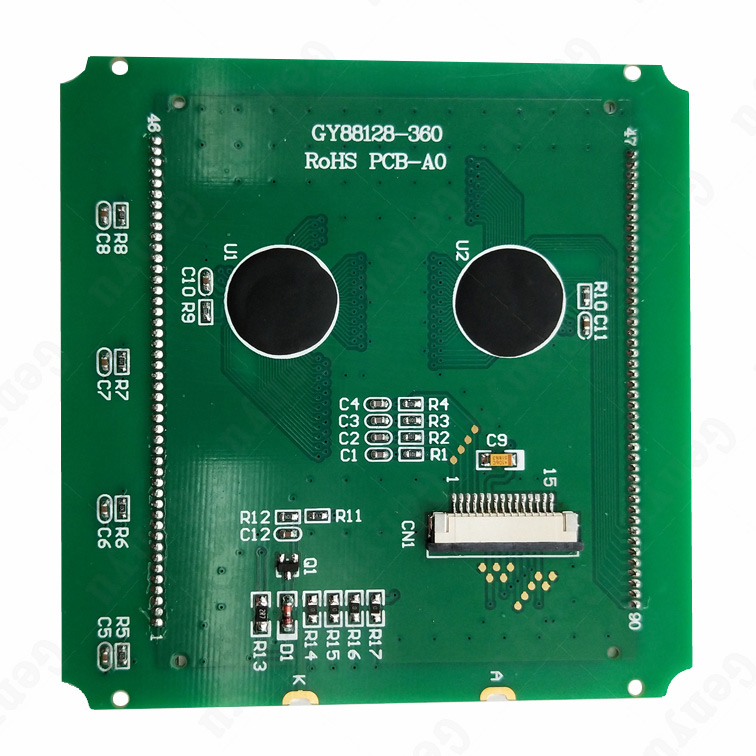

SMT: This process is one of the manufacturing processes for Liquid Crystal Display Boards. It is the placement of mounted components (chips, resistors, capacitors, etc.) on the solder pad position of the PCB with the solder mask, and through the backflow equipment to achieve components in the PCB board on a welding process.

Tab: This process is a process in which the flexible tape with drive circuit is bonded through ACF and hot pressed at a certain temperature, pressure and time to connect the screen to the drive circuit board.

Above is the LCD LCD IC packaging in 5 ways.

Copyright © 2019 Shen Zhen Genyu Optical Co., Ltd. | All Rights Reserved